CHAPTER X

Logistics

The supply of repair parts has long been recognized as one of the major problems in the maintenance program of the U.S. Army. The volume of equipment furnished a modern army is tremendous and the slight differences between "identical" parts which come from being produced by different manufacturers add to the problem. Ordering and receiving the right part becomes a precision task. Updated manuals are needed for parts identification, and an error in one digit on a stock number from an outdated reference can result in the wrong part or no parts at all. The volume and complexity of the task is mind boggling.

Many units in Vietnam listed acquiring spare parts as one of their main logistical headaches. They tried different approaches to resolve the problem. Some units tried to beat the supply system by having their men scour the depots to locate parts and major items of equipment and requisition them on the spot. Other units, such as the 25th Infantry Division, tried to make the system work. Colonel Tom Ferguson in reflecting on his experience as the division signal officer, stated, "We faithfully followed the Technical Manual 38-750 concept at all times, and with excellent support from the division support command and somewhat tenuous faith in the Army supply system we were able to maintain our equipment." Some used the system and some used modifications of the system, and both were made to work satisfactorily. The conscientious and traditionally ingenious American soldier would make the system work-even if, at times, he had to bend it slightly. Higher echelons soon attacked the problem from their levels and instituted a number of improvements.

The closed loop support system was established to control the flow of critical components or assemblies to and from respective commands in hope of supporting prescribed levels of equipment readiness. Supply, retrograde, overhaul, and resupply were given special attention to ensure that critical items were quickly overhauled and rebuilt and then quickly returned to the supply system. This system allowed units to exchange critical items directly. The

[77]

system was generally successful with radar and teletypewriter equipment but less so with radio equipment because replacement items were not available for direct exchange. One innovation that made the system more efficient was the "jiffy bag," a cushioned paper bag in which small modules and components could be shipped for repair and returned safely and quickly.

Problems in the receipt, issue, and distribution of communications-electronics equipment and repair parts grew from the lack of signal expertise at logistics depots. Most people who worked these were not versed in the increasing sophistication and technical makeup of equipment and components and the volume of communications-electronics supply.

At the division level, the primary logistical organization was the division support command (DISCOM). With its supply and service, transportation, maintenance, and medical battalions, plus its administration company and its headquarters company and band, the support command was both a customer of the communications system and a major supporter. The supply and service, transportation, and the maintenance battalions played a major role in keeping the communications equipment operating. They supplied repair parts and replacement items and maintained and repaired equipment when the units could not.

The division signal officer had to maintain a close relationship with the commander of the support command. The success of the communications system depended, to some extent, on the effectiveness of support the command provided. The support commands were vital not only in division communications but also in combat. A number of division commanders considered the support commands so important that they assigned some of their most experienced officers to head them. The division commander or command section did not always realize that the support command was ultimately responsible for supply and repair parts for signal equipment within the division. The division signal officer frequently had to resolve supply problems which were beyond his scope.

Most of the units in Vietnam centralized their maintenance systems. Time and distance and the immediate tactical situation, however, often dictated something between complete centralization or decentralization.

Tactical units operating in Vietnam received power for their communications equipment from fixed plant generators, portable generators, and batteries. Civilian contractors operated fixed generators in some of the base camps. Portable generators were used extensively and were important in division communications. They

[78]

were usually three-, five-, or ten-kilowatt. When air conditioning was necessary for the efficient operation of some communications equipment, the ten-kilowatt air-cooled generator became the workhorse. Originally the ten-kilowatt generators were used only for powering signal equipment but the signal sections at base camps and other sites had to provide power for many other purposes, perimeter lights for example. On smaller landing zones, signal often became synonymous with the responsibility for providing all electrical power at the location.

Commands had to emphasize maintenance if the generators were to survive under heavy use. Heat, wind, and sand were constant enemies, and inadequately trained and improperly supervised operators often compounded the maintenance problem. Operators frequently were trained in the operation and maintenance of the motor but not the generator or trained to operate the system but not to maintain it. As a result, most units placed generators high on their list of problems.

Batteries were used in every vehicle, every generator of five kilowatts and above every telephone switchboard, every tactical telephone, and most tactical radios. The Vietnam climate was the biggest enemy of batteries, both wet- and dry-cell. In the heat and humidity, the wet-cell battery reached its boiling point quickly and stopped working. Operators had to service cables, battery boxes, electrolytes, and connectors more frequently than normal to prolong battery life. Dry-cell batteries also were not immune from the Vietnam temperatures. They had to be kept in a cool, dry place. The recommendation that batteries be stored under refrigeration until issued to the troops was not commonly followed at the lower levels, where any refrigerated space normally was reserved for perishable foods and medical supplies. Dry-cell batteries were often stored in any available container, for example a steel Conex container which changed temperature drastically from day to night. This storage method gave many units batteries that operated for only a fraction of the normal time.

One of the heaviest users of the dry, zinc and carbon oxide batteries (BA-386) was the AN/PRC-25/77 manpack radio employed by most tactical units. As voice secure transmission became more common, the usage requirements of these batteries, which had to be used in both the radio and security device, increased significantly. To increase dry-cell battery life, the magnesium battery (BA-4386) was developed and first used in early 1968. The magnesium battery lasted almost twice as long as the zinc and carbon oxide battery and it did not have to be refrigerated. The mag-

[79]

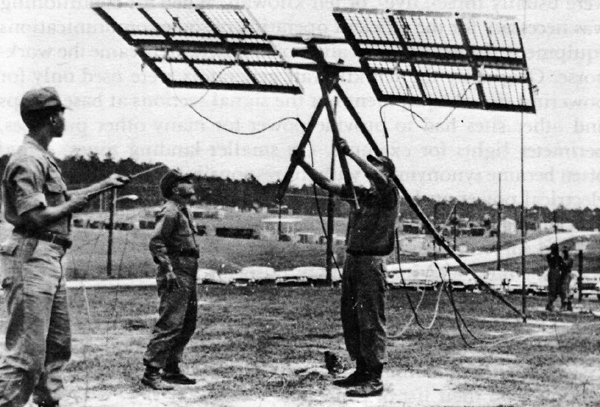

STUDENTS ERECT ANTENNA at Willard Training area, Fort Gordon, Georgia.

nesium batteries, however, generated a hydrogen gas which in a closed container built up and caused the batteries to explode and burn. Storing the magnesium batteries in a well ventilated area solved this problem.

Batteries in storage were not always rotated to ensure that older stock was used first, and some became useless. Though the magnesium battery was a distinct improvement and means were developed to reduce or eliminate problems, batteries as well as generators were high on the problem lists of most units.

From 1965 to the final redeployment of tactical units, numerous communications-electronics assemblages were introduced in Vietnam to upgrade the quality and quantity of tactical communications. In many cases, these assemblages consisted of whole families of equipment designed to replace obsolete gear. The AN/PRT-4 and PRR-9 squad radios replaced the AN/PRC-6. The AN/PRC-25 and 77 short-range FM radios replaced the AN/PRC-8-10. The AN/VRC-12 series FM radios replaced the RT-66-67-68/GRC (including AN/GRC 3-8, VRC 7-10, VRC 20-22, and VRQ 1-3 sets). And the AN/GRC-106 AM radios and teletypewriter replaced the AN/GRC-19. These four basic systems provided communications at specific levels or filled distinct needs.

The new two-piece, lightweight squad radio greatly increased

[80]

the capacity of squad communications. It consisted of a two-channel hand-held transmitter, the AN/PRT-4, and an ultra-miniature helmet-mounted receiver, the AN/PRR-9. Designed to provide short-range (500-1,600 meters) tactical communications in the combat areas, it replaced the hand-held receiver and transmitter which was used for communications between squad and platoon. The new radio was considerably smaller, lighter, and more efficient than the older PRC-6 and could communicate with the VRC-12 and PRC-25/77 radios as well as with the PRC-6. It was used primarily within and between squads but could be used by larger units for other kinds of tactical missions. The squad radio was issued in early 1967 and by late that year was available to all tactical maneuver units. Units using the new radio varied in their opinion of it. Most would trade it for the AN/PRC-25/77 whenever possible for greater range and reliability. They considered the squad radio most effective in relatively static situations such as perimeter defense.

The AN/PRC-25, a short-range FM radio, was modular and was transistorized except for a power amplifier tube. The radio was used in three basic configurations, manpack (PRC-25), vehicular (VRC-53), and manpack or vehicular (GRC-125). The first PRC25's in Southeast Asia (mid-1965) were intended for advisers. With their initial distribution came the first new equipment training (NET) team from the Electronics Command to begin instruction on the operation and maintenance of the VRC-12 and the PRC-25.

The AN/PRC-77 set was an improved version of the PRC-25. Completely solid state design made it more reliable. It also needed less power and could be used for secure voice communications. The PRC-77 was basically a manpack radio but also could be used in the three basic configurations, manpack (PRC-77), manpack or vehicular (GRC-160), and vehicular (VRC-64). The PRC-77 was compatible with the VRC-12 and PRC-25 families, with the ARC54 aircraft radio set and with the PRT-4 and PRR-9 squad radio. The PRC-77 was organic to battalion-size units and was issued through platoon level.

The radio sets AN/VRC-12 and VRC-43 through VRC-49, commonly referred to as the AN/VRC-12-series, were the new vehicular radio communications equipment used extensively by combat units. These FM radio sets replaced the AN/GRC-3 through GRC-8 series. The new sets consisted of various combinations of two basic components, a receiver-transmitter and an auxiliary receiver. The receiver-transmitter came in two versions, the RT246 and the RT-524. The RT-246 could select one of ten frequen-

[81]

cies preset by the operator. The operator had to select each frequency manually on the RT-542, which had a built-in loudspeaker in the space occupied by push buttons on the RT-246. The RT-524 was developed primarily for use in vehicles where the operator could reach the control panel easily; the RT-246 was designed for use in tracked vehicles where the operator could not reach the control panel. In Vietnam this equipment was often removed from vehicles for use in bases such as forward tactical command posts. In most cases, major tactical units were issued the VRC-12 family of radios just before or shortly after their deployment to Vietnam during 1965 and 1966.

The high frequency communications system within a divisional area of operations were used almost entirely for radio teletypewriter operation. The AN/GRC-46 or the AN/VSC-1 AM radio teletypewriter sets gave the maneuver battalions their only means of secure printed communications. At brigade and division levels, radio teletypewriter for the most part provided only a backup for the multi-channel secure teletypewriter circuits. The GRC-19 was replaced in 1966-67 by the newer high frequency single sideband radio set AN/GRC-106 with its radio teletypewriter configurations, the half duplex AN/GRC-142 (AN/VSC-2) and the full duplex AN/GRC-122.

The AN/MRC-69 was a frequency division multiplex radio relay carrier terminal set which could provide twenty-four telephone channels and twelve teletypewriter channels: It was normally used at division and brigade levels as a dual radio carrier terminal providing two twelve-channel systems. The set was the backbone for the divisions' multi-channel systems. It was available in numerous equipment combinations (in addition to the basic MRC-69) such as the single terminal MRC-73, the telegraph telephone terminal MCC-6, and the radio repeater MRC-54.

The airmobile and airborne divisions needed a lighter, more mobile system. With the organization of the 1st Air Cavalry Division, a trend toward lighter systems began and resulted in the MRC-111 and MRC-112. Although they could be transported by helicopter easily, they provided only four channels. These were followed by the AN/GRC-163, a lightweight, four-channel, single terminal radio consisting of the VRC-47 and a multiplexer (TCC-70). The GRC-163 had a communications planning range of fifty miles and provided multi-channel communications between brigade and battalion where wire lines were not tactically feasible. The GRC-163 was designed for use in airmobile operations and was compatible with the VRC-12 and PRC-25 series of

[82]

radios. Unlike the larger, heavier MRC-69 and MRC-112, the set was small enough to be airlifted in assault helicopters. Kits were also available for installing it in a quarter-ton truck or trailer. GRC-163's were first shipped to Vietnam in January 1968 and were accompanied by a two-man training team from the Electronics Command. Another four-man team was sent to Vietnam in August 1968 to train personnel of the 1st, 4th, and 9th Divisions to install, operate, and maintain the set.

[83]

|

Go to: |

|

Last Updated 3 October 2003