MAP 7

CHAPTER VII

Engineer Mobilization and Performance

On Christmas Eve of 1965 President Johnson declared a halt in the bombing of North Vietnam as part of his "peace offensive" that was to last through the first month of the new year. His efforts to negotiate with the North Vietnamese through representatives of neutral countries met a flat refusal from Hanoi that dashed all hope of an early end to hostilities. Bombing was then resumed and American forces attempted a military solution by mounting a campaign designed to seize the initiative and carry the fight to Viet Cong strongholds. It was at the beginning of the peace move that the last engineers for some time to come arrived in Vietnam.

On New Year's Day 1966 the 20th and 39th Engineer Battalions, along with the 572d Engineer Company (Light Equipment), landed at Cam Ranh Bay and joined the 35th Engineer Group. With the exception of two separate companies that came in May and the 169th Engineer Battalion (Construction) that joined the 159th Engineer Group at Long Binh from Okinawa in April, no more engineer units would arrive in Vietnam until summer. During these months the 18th Brigade concentrated on providing the operational, logistical, and support facilities required for the rapidly expanding U.S. military forces. The plan for base development was to construct several deep-draft ports with satellite shallow-draft ports; to build major airfields, depots, and logistical facilities at the port complexes; to extend the land lines of communication inland from the ports; to build the necessary troop bases throughout the country; and finally to expand the roadnet to connect the major bases. As American participation in tactical operations increased, additional engineer effort had to be devoted to combat support. Concentration on base construction became impossible, though every effort was made to give each project some attention.

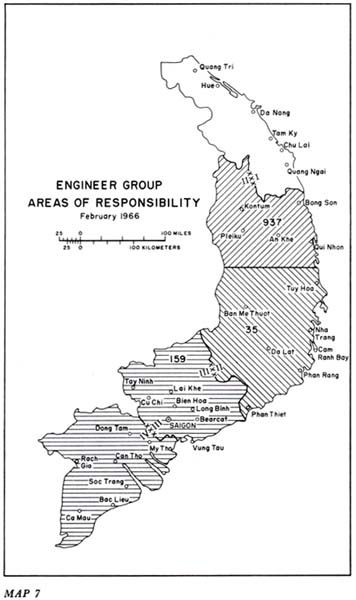

Although engineer forces in Vietnam at the beginning of 1966 still consisted of a single brigade with three subordinate groups, demands for engineer support mounted rapidly as American combat forces continued to stream into the country. (Map 7) Their arrival

[84]

[85]

necessitated a more extensive deployment of engineer troops throughout the 67,108 square miles of South Vietnam and created problems of command and control. Since all nondivisional engineers were either attached or assigned to the 18th Engineer Brigade and the brigade, in turn, to U.S. Army, Vietnam, no direct relationship existed between the brigade, its groups and battalions, and the combat forces. Direct coordination between the field force and divisional engineers and the engineer groups was authorized and encouraged, and was usually accomplished through an exchange of visits between field force, division, and group staff members. To facilitate coordination and utilize fully individual expertise, junior officers were often delegated responsibilities far beyond those usually assigned to them. The commander of the 18th, General Ploger, found that his junior officers responded to the demands made upon them with an ingenuity and resourcefulness that made them one of his great assets.

As commanding general of all nondivisional engineer troops in South Vietnam and as the Army Engineer on the staff of U.S. Army, Vietnam, General Ploger had dual responsibilities, an arrangement that conserved scarce manpower resources by eliminating the need for duplicate staffs at brigade and U.S. Army, Vietnam, levels and reduced the number of problems between planning and operating elements. Aware that charges of self-serving could easily arise from the potential power inherent in his position, General Ploger insisted that all construction priorities reflect the engineers' primary mission of combat support. The combination of his two offices gave General Ploger both procurement and management powers as well as an ideal position from which to supervise the allocation of equipment and material resources.

Vesting in one man both staff and command responsibility had long been doctrine in the U.S. Army at both division and corps levels of organization. When the 18th Engineer Brigade arrived in South Vietnam the logistics office of the U.S. Army, Vietnam, headquarters included a small engineer section staffed by Lieutenant Colonel Andrew Gaydos and one or two enlisted men. The larger engineer office in U.S. Military Assistance Command, Vietnam, was concerned with formulating policies to apply to Army, Navy, and Air Force activities, and could not cope with the coordination needed in the staff of the U.S. Army, Vietnam. Accordingly, the normal Army engineer tasks of coordination, of computing material requirements, of recommending priorities, and of advising the deputy commanding general of U.S. Army, Vietnam, General Norton, on engineer matters were initially absorbed by the staff of the 18th Brigade.

[86]

When Colonel William W. Watkin, a senior engineer officer who was seeking to withdraw from his position as a permanent professor at the United States Military Academy, arrived in September, he was appointed Deputy Army Engineer as a part of the USARV staff. Subordinates were drawn from several elements of the 18th Brigade to obtain a full operating engineer section that could respond to demands for information on engineer matters from higher headquarters outside South Vietnam. At first the section gave its attention to supply computations, Army real estate policies, repairs and utility policies (implemented by the engineer contractor element of the 1st Logistical Command), and the rapidly changing plans for receiving incoming tactical and logistical units.

From the very early days of the buildup General Ploger functioned through two deputies, Colonel C. Craig Cannon in the brigade and Colonel Watkin in Headquarters, U.S. Army, Vietnam. When Colonel Cannon was reassigned as a brigadier general selectee in December of 1965, he was promptly replaced by Colonel Paul W. Ramee, who had just arrived and who remained a deputy commander until the Engineer Command was formed in December of 1966. At that time Colonel Ramee became the acting commander of the brigade and moved its headquarters to Dong Ba Thin, adjacent to Cam Ranh Bay. Colonel Watkin left his deputy position in February of 1966 to assume command of the 937th Group at Qui Nhon. His successor, Colonel Roland A. Brandt, stayed only three months before he was replaced by Colonel Frank E. Walker, Jr. Thus, throughout the hectic buildup period, the upheavals that the engineer structure in South Vietnam underwent matched those of many other functional organizations within U.S. Army, Vietnam.

The dual-role concept for the engineer headquarters of U.S. Army, Vietnam, received added support when similar concepts were adopted for medical services, whose commander was the USARV surgeon; the military police, whose commander was the USARV provost marshal; and the aviation brigade, whose commander was the USARV aviation officer.

As the U.S. Army corps headquarters were formed-Headquarters, I Field Force, Vietnam, at Nha Trang and Headquarters, II Field Force, Vietnam, at Long Binh-they were not provided with normal complements of organic engineer units.

The "corps" engineers' lack of engineer units to command first became evident as a potential source of difficulty in operations in II Corps Tactical Zone, but the engineers' avowed principle of priority support to tactical operations gave Colonel Edward L. Waddell, the corps engineer of I Field Force, operational control of engineer troops needed in any operation. The directed responsive-

[87]

ness of engineer commanders combined with Colonel Waddell's flexibility fostered the development of standards of procedure which led to repeated successes on the battlefield and at the same time allowed great progress in construction.

Construction Standards and Priorities

In the face of mounting demands for construction but with limited construction resources, U.S. Army, Vietnam, took steps to insure the most effective utilization of engineer manpower and material. After General Ploger had briefed General Westmoreland on construction standards in November, he traveled to each command headed by a general officer to acquaint the commanders promptly with the standards and priorities approved by the Army commander.

Self-sacrifice meanwhile became the hallmark of the engineers as they worked almost around the clock for the units they supported. Their own facilities went unimproved for the most part because the so-called free time which would have allowed the engineers to work on their own camps and cantonments was an almost unknown commodity. At no time did engineer units enjoy a higher standard of living than the combat units they supported, but they enjoyed a high morale derived from their sense of purpose and their pride of accomplishment in the face of obvious need, and they garnered the utmost respect from field commanders.

Just as construction standards were necessary to assure the orderly accomplishment of the formal construction program, construction priorities were intended to make certain that the full range of support facilities was provided for tactical operations. Any list of priorities had to be realistic enough to reflect current engineer capacity, which was dependent upon equipment and materials on hand. It also had to be flexible enough to allow changes, for it was occasionally necessary to shift men and material from project to project almost on a daily basis. Nonetheless, maintaining at least theoretical priorities in the field provided a basic framework for construction in a situation ripe with potential chaos. The priorities, as will be seen, did change. One of the first and very significant changes concerned tents. Early in 1966, it became evident that tentage could be expected to survive little more than one year in the severe climate. Then, by decision of General Westmoreland, the erection of wooden tropical shelters for troop quarters was accepted, to be accomplished at each site as soon as practicable.

The delineation of construction priorities provided not only a sequence for concentrating engineer effort but also a check rein on

[88]

BASE DEVELOPMENT AT QUI NHON,

showing transition from tents to more permanent facilities.

requests for construction that was not essential. Requests from some field commanders for the more sophisticated comforts reflected a poor understanding of the extent of the engineer work load. A listing of the work to be done and the order in which various tasks were to be undertaken gave such commanders a better picture of the engineer situation.

The engineers devoted themselves during the first half of 1966 primarily to base development, which, although it encompassed almost every phase of engineer activity, was still concentrated near large logistical and tactical complexes. The necessity for developing fixed, relatively permanent bases from which to operate was accepted and appreciated by commanders at all levels. But with the increase in the number of tactical operations, engineer effort would soon be drawn more deeply to combat support.

All engineer activity was by its very nature geared to support tactical operations. However, the engineers involved in the most

[89]

SOLDIERS OF 8TH ENGINEER BATTALION RAPPELING FROM HELICOPTER

direct support of combat forces were those organic to the combat formations, the divisional engineers. The doctrinal mission of an engineer battalion organic to a division is to increase the combat effectiveness of the division by performing various engineer tasks and, when necessary, fighting as infantry. To use other terms, the mission of the divisional engineers in Vietnam was to improve the mobility of friendly forces and to impede the mobility of the enemy. Their specialized skills and equipment were often of vital importance in sustaining the impetus of an offensive operation carried out by U.S. and allied troops.

Engineer demolition teams were frequently called upon in combat operations to destroy enemy base camps, material, and tunnels. Divisional engineer battalions often designated one of their subordinate engineer teams to support an infantry company on operations involving larger formations to assure immediate engineer assistance on every unit level. When the teams did not actually accompany the infantry units on their operations, they stayed in rear areas on alert so that they could be immediately airlifted to the point where they were needed. Besides destroying

[90]

enemy fortifications and bunkers, those engineers assigned directly to divisions also assisted in the preparation of defensive positions, in minesweeping, and in the rapid preparation of landing zones. The airmobile concept of warfare was coming into its own in Vietnam and the use of the helicopter in tactical operations led to the development of new expedients for preparing landing sites. Beginning in January 1966 U.S. And Vietnamese forces conducted a series of operations intended to seek out and destroy the enemy in what had been his sanctuaries. It was during these operations that the procedure for constructing forward landing zones by the use of flying engineer teams was developed.

The 8th Engineer Battalion, as part of the 1st Cavalry Division (Airmobile), refined the technique of using helicopters to transport an engineer platoon or squad to the landing zone site. The engineers were flown to a site and would then descend by means of a "troop ladder," or rappel, from the hovering helicopter to begin clearing operations with demolitions and chain saws. A landing zone for helicopters usually could be cleared in a matter of minutes using this technique.

Later a more expeditious method was devised for preparing bigger landing sites. A large bomb was dropped over the jungle by an aircraft and detonated above ground to gain maximum effect from the force of the blast and to prevent cratering within the site. Carrying the necessary land-clearing equipment, Army engineers then descended to the site from helicopters and enlarged the opening enough to allow a special air transportable bulldozer to be lowered into the area for more extensive land clearing. Approach zones were created by blasting away the dense foliage at each end of the landing site. In supporting roles such as this, engineers made it possible for American and South Vietnamese combat forces to reach hitherto inaccessible areas where they could challenge the enemy. The Viet Cong and North Vietnamese forces soon learned that there was no place in South Vietnam impervious to assault by large forces of U.S. And Vietnamese troops.

Another engineer contribution to operational support was mine clearing. Minesweeping was conducted daily in less secure areas of operation adjacent to base camps. The 8th Battalion, for example, had to check a twelve-mile stretch of road along Route 19 in the vicinity of An Khe every morning before troops or vehicles could be allowed to traverse it. Throughout 1966 sweeping operations were conducted almost exclusively by teams of men traveling the miles of roadway on foot. Although many attempts were made to speed up minesweeping by using such devices as jeep-mounted mine detectors or multiple-wheeled rollers extended from the front of

[91]

tanks, each new device caused supply and equipment difficulties and none was wholly successful.

Although extensive land-clearing operations were conducted by divisional engineers in several large-scale offensives, nondivisional engineers were best equipped to handle major clearing. Tank dozers of the division battalions were used for smaller more localized tasks such as plowing through booby-trapped perimeters of enemy base camps and cutting short paths for the advance of the infantry.

The search and destroy tactics developed by U.S. commanders in 1966 paid immediate dividends by uncovering enemy supplies and munitions. The reconnaissance conducted during such operations often disclosed enemy sanctuaries in the form of vast networks of tunnels. One such complex used by the Viet Cong in the III Corps Tactical Zone was probably as much as twenty years in the building. Constructed in impervious layers of hard clay at varying depths, with small, well-camouflaged entrances, these tunnels defied any simple method of destruction. Most of them had no electric power and lighting nor forced ventilation; they were large enough for the Vietnamese to crawl through comfortably but Americans could get through them only with difficulty.

[92]

ENGINEER TUNNEL DEMOLITION TEAM. "Tunnel rat" is preparing to place

charges and make connections for detonation. Note smallness of access hole which

is easily camouflaged.

[93]

A thorough search of the tunnels often produced significant intelligence concerning the strength and intended operations of the enemy within the area. Once the complexes had been thoroughly searched, the problem remained as to the best method of destroying them so completely that they could not easily be repaired by the enemy and used again.

Generally, enemy tunnels were of two kinds: simple, shallow structures, hastily built and used primarily by local Viet Cong and guerrillas, or well-constructed systems used by large forces and usually found in uninhabited areas. Tunnels varied in length from twenty to over ten thousand feet. The larger networks were sometimes quite elaborate, having as many as four distinct levels and consisting of large compartments usable as living quarters, hospitals, and mess facilities. Some even contained facilities for manufacturing and storing war materials.

Finding the cleverly concealed tunnel entrance often was the most difficult part of tunnel destruction. Once an opening was located, smoke grenades were thrown in to drive out enemy troops and any civilians who were being held as hostages. The tunnels could then be searched.

Exploration was usually conducted by two-man teams. While one man stayed at the entrance the other descended into the tunnel equipped with a phone, communications wire, compass, bayonet, flashlight, and pistol. As he explored the network, the man in the tunnel maintained communication with his partner at the entrance, to whom he reported his progress, findings, and changes of direction. The man on the surface recorded all such information as it was received.

Several methods of destruction were used once the tunnel had been completely searched. For tunnels within ten feet of ground surface, acetylene gas was used. Necessary equipment included chemicals for making acetylene gas, air blowers, and small explosive charges. Acetylene generated on the spot was forced into the tunnel by blowers and, with all openings sealed, the small charges were detonated, thereby exploding the mixture of acetylene and tunnel air. The roof of the tunnel usually collapsed. The results were frequently less effective than desired because the explosive gases were not completely mixed. Introducing oxygen at the time the acetylene was generated produced better results but aggravated the logistical aspects of the operation. Understandably the tactical commanders were disinclined to keep combat troops in alert security status after a tactical operation in order to allow time for deliberate destruction of Viet Cong tunnels. Consequently, engineers were constantly seeking faster and more effective means of destruction.

[94]

For tunnels deeper than ten feet, charges were placed in a series at 100-foot intervals on the floor of the passageways and sacks of powdered riot-control agent C2 were placed on top of the charges. When the explosives were detonated the C2 was blown into the walls between the collapsed sections. The chemical remained effective from two to six months and made remaining sections of the tunnel uninhabitable.

Efforts at determining tunnel traces from the surface met only partial success. Obviously destruction by surface means should have been the most effective way of eliminating tunnels. Another means that was investigated was destruction by flooding. This solution, for an engineer, was not unlike trying to fill all the water pipes in a new house by feeding water into an open pipe at the second story level. Without knowing all the potential air locks and without sealing all but the appropriate single outlet, there was scant hope of success. Moreover, the sheer volume of water which might be required was enough to give anyone pause.

Land clearing was another important job of the engineers in their operational support role; in fact, engineer methods of land clearing gained wide acceptance as among the most effective tactical innovations of the war. As techniques evolved for the employment of land-clearing units, these units more and more became the key elements in successful operations aimed at penetrating enemy strongholds, exposing main infiltration routes, denying areas of sanctuary, and opening major transportation routes to both military and civilian traffic. Engineer land-clearing troops on many occasions formed the vanguard of assault forces attacking heavily fortified enemy positions, while even under ordinary circumstances their use in clearing the jungle ahead of tactical security elements placed them routinely in a position of direct vulnerability to enemy action. These engineer troops rapidly developed a zestful pride in the importance, difficulty, and hazards of their occupation, and while their deportment and appearance sometimes fell short of normal standards, their spirit, courage, and persistence under the most adverse conditions entitled them to a substantial claim to elite status.

In the vocabulary of U.S. forces in Vietnam, Rome Plow came to be synonymous with land clearing. Of all the various types of land-clearing equipment tested in Vietnam, the military standard D7E tractor, equipped with a heavy-duty protective cab and a special tree-cutting blade manufactured by the Rome Company of

[95]

Rome, Georgia, proved to be by far the most versatile and effective. The tractor took its name from its most imposing feature-the huge blade on the front.

The giant Rome Plow blade was designed to move over the ground six inches above the surface, shearing off most of the vegetation but leaving the root structure to prevent erosion. The blade has a leading knife-edge that Was sharpened by a portable grinder at least once daily. It is slightly angled so that cut material is discarded to the right. The leading corner of the blade is extended by a rigid "stinger" with which the operator attacks the larger trees by a succession of stabbings and dozer turnings.

The potency of the Rome Plow was early recognized by the troops in the field. Lieutenant General Julian J. Ewell, commander of II Field Force, was so impressed that he was led to remark that the Rome Plow Was "the most effective device" for winning the war. It played a substantial role not only in achieving military success but also in building the South Vietnamese economy through land clearing for redevelopment purposes.

An integral part of the land-clearing operation was aimed at improving security along roadways. No road, no matter how well

[96]

LAND CLEARING ON BOTH

SIDES OF A PUBLIC ROAD to reduce chances of enemy ambush.

constructed, was of much value if enemy interdiction made the use of it too hazardous. Wherever a highway passed through jungle or heavy brush in areas subject to enemy activity, the land had to be cleared on either side for distances up to a hundred meters. The Rome Plow was the principal tool in these clearing operations. When the cover provided by the brush was removed, it was difficult for the enemy to stage an ambush. In addition, the land cleared by the plows was often fertile enough for farmers to move in and cultivate.

The story of how the Rome Plow reached the U.S. Army in Vietnam and came to be one of its most effective weapons merits recounting. U.S. Military leaders had recognized early the tremendous advantage the jungle offered the Viet Cong and North Vietnamese Army in terms of limiting the movement of firepower of the modern military equipment employed against them and in protecting their bases, their lines of communication, and their arsenals. As early as November of 1965 General Westmoreland put his staff to work looking for means of jungle clearing. An officer was dispatched to Australia where success had been reported with a ten-ton or heavier hollow ball approximately twelve feet in diameter towed

[97]

THE LETOURNEAU TREE-CRUSHER could fell large trees and cut moderate size

timber into sticks which were pressed into the ground.

by ship anchor chains linked to a pair of very heavy tractors. This towed ball worked well in the Australian jungle, but when attempts were made in Vietnam to fabricate some sets of balls and chains, the large size of the ball, the difficulty of transporting it, and inadequate equipment stood in the way of an early success. Suggestions from the United States meanwhile included a 100-ton tracked tanklike vehicle, the three-wheeled LeTourneau tree-crusher, and a Rome Plow attachment for military tractors. A small number of tractors with Rome Plow attachments and accessories were ordered at once. Within hours after they had arrived, been assembled, and been hurried through field tests, large orders for Rome Plow kits were under preparation. While awaiting delivery, the test models in South Vietnam were put to immediate use and organizational training and operating plans were developed. The 100-ton tank was rejected as too hard to move; getting it from ship to shore in South Vietnam and subsequently to the jungle would have created impossible problems.

The LeTourneau tree-crusher was also originally rejected, even though it was capable of being broken down into four or five pieces for shipment. Flotation characteristics were appealing, but it was only marginally effective in the water. Although it weighed sixty tons, it was less trouble to move than some other proposed devices,

[98]

but it was vulnerable-a target too big to miss in a tactical situation; a complex, though well-protected hydraulic system; and little prospect of extracting the machine if it became deadlined in the middle of the jungle. Nevertheless, the commanding general of the 1st Logistical Command arranged for rental and shipment of a test model to the Long Binh area. In the early spring of 1967 the treecrusher proved its ability to perform in a swampy jungle; however, it was not reliable enough in South Vietnam and was returned to the United States when the lease expired.

The Rome Plow meanwhile had already fully demonstrated its suitability in major tactical operations. By the summer of 1967 three land-clearing platoons (or teams as they were called at that time) were operating in Vietnam, each equipped with thirty Rome Plows. Two platoons were assigned to the 20th Engineer Brigade, which was supporting II Field Force, and the third was assigned to the 18th Engineer Brigade, which was deployed in I Field Force. In addition, land clearing on a lesser scale was carried out by other engineer units throughout Vietnam, particularly by the divisional engineer combat battalions.

As the intensity of U.S. involvement in the conflict increased, the requirement for additional land-clearing units became apparent. The need for organizational changes was also recognized since many tactical units to which land-clearing teams were attached experienced an almost traumatic drain on their command, administrative, and, particularly, their maintenance capabilities. With only sixtyfour men, a land-clearing team could contribute little more than a complement of operators for its thirty Rome Plows under the operational conditions that existed. Consequently, in December 1968 the three land-clearing teams were reorganized as companies with thirty Rome Plows each and were also provided with a significantly better capacity for self-support, particularly in maintenance. One month later, in January 1969, three additional land-clearing companies were activated, bringing the total to six, a number that was maintained until April 1970 when one of the companies was inactivated under the terms of the phase-down.

Three of the land-clearing companies were assigned to the 20th Engineer Brigade and three to the 18th Engineer Brigade. The 20th Engineer Brigade area of operation included large, reasonably level tracts in III Corps Tactical Zone that were occupied by major enemy units. These areas were particularly in need of land-clearing operations; furthermore, the roadnets were adequate for the large convoys of heavy tractor-trailers which transported land-clearing companies from a central base to the cutting area. These factors were prominent in the decision to organize a land-clearing battalion that would

[99]

incorporate the three land-clearing companies of the 20th Engineer Brigade. The 62d Engineer Battalion based at Long Binh was selected for this purpose. Its lettered construction companies were inactivated, and in January 1969 the 62d was assigned the 60th, the 501st, and the 984th Engineer Companies (Land Clearing) to perform the mission of land-clearing operations in support of II Field Force.

The 18th Engineer Brigade supporting I Field Force in Military Regions I and II was faced with a different situation. Although objectives were plentiful enough in the form of enemy strongholds, the terrain was severely restrictive and so were the roadnets. Therefore the 59th, 538th, and 687th Engineer Companies (Land Clearing) were employed and supported on the basis of a geographic area of responsibility, with one company assigned to each of three engineer groups. Regardless of the method of deployment, land-clearing operations were closely controlled by the field force commander concerned. Since requests for Rome Plows far exceeded their availability, high-level control was essential to assure that land-clearing units were used only for tasks of the highest priority.

Much was learned from the employment of the original landclearing platoons on large-scale clearing operations in 1967. Techniques were developed and perfected in planning and execution in order to solve such exceptionally difficult problems as controlling an operation in dense jungle and coordinating the actions of the combat security force and the engineers operating the Rome Plows-particularly when troops were engaged with the enemy. The extreme heat, the dust (or mud during the monsoon season) , large falling trees, bomb craters, hidden ravines, and enemy mines took a serious toll of equipment and accessories. Probably no item of equipment was ever operated so far beyond the limits of its designed capabilities as was the Rome Plow tractor in Vietnam. Yet this problem, too, was overcome, at least to the extent that the cost of land-clearing operations was brought to an acceptable level. The organizational changes mentioned earlier formed part of the solution; so did the establishment of direct dealings between land-clearing units and major logistical support facilities. But most of the solution was provided by the land-clearing engineers themselves. Once these men learned what it took in terms of skill, hard work, inventiveness, and just plain desire to keep their equipment operating, they did it. It became routine for a plow operator to spend twelve hours clearing jungle under conditions of extreme physical discomfort and hazard, and then return to the night defensive position and work for six or eight more hours in the darkness repairing his tractor for the honor of being able to repeat the cycle on the

[100]

following day. Since operations generally lasted forty-five days before a unit was allowed a fifteen-day maintenance stand-down at its home base, the plow operators were called upon for almost unbelievable self-sacrifice. Without their heroic efforts the cost of landclearing operations on any significant scale would have been prohibitive.

For the uninitiated observer, a visit to a land-clearing unit was unforgettable. The operation was conducted from a hastily constructed nighttime defensive position which, depending on the season, was rapidly churned by the tractors into either a bowl of choking dust or a sea of impassable mud. This was home for a task force that consisted of a land-clearing company and a security force, the latter normally of at least company strength and preferably mechanized. As the clearing progressed the night base was moved, usually every five to seven days, to a new location. Each day's clearing was carefully planned the previous evening by the security force commander, who was usually in over-all charge of the operation, and by his supporting land-clearing commander. Planning included the exact delineation of the area to be cleared, the deployment of security forces, the routes to be followed to and from the cut, special

[101]

procedures to be followed in case of enemy contact, and the use of preparatory and supporting artillery and small arms fire. Because of difficulties in navigating in heavy jungle, the operation was controlled as a rule from a helicopter by an officer from the land-clearing unit. The lead tractor was guided by radio in cutting a trace or outline of the area to be cleared while the remaining plows followed in an echelon formation, leaving in their wake an ever-widening swath of cleared jungle. Once the trace was completed, the most difficult navigational problem was over, and the formation of plows continued around the decreasing perimeter until the area of jungle was eliminated. The vehicles of the security force followed the plows as closely as they were able. Quite often it was necessary to assign tractors to push fallen trees aside to permit passage of the combat vehicles.

In the course of a day it was common for one-half to two-thirds of the Rome Plows to sustain disabling damage of some sort. Much of this damage was repaired on the spot by a team of mechanics. In other cases the plow had to be towed back to the night defensive position. Since the operational area was often inaccessible by road, removal of the damaged equipment was complicated. For this reason land-clearing troops developed enough skill to make repairs in the field that were ordinarily made in depots. It was not unusual to have a tractor hauled into its defensive base, disassembled to its very framework, fitted with new major components, and returned to service in just two or three days. To meet the massive demands of a land-clearing company for spare parts, daily deliveries by Chinook helicopter became routine.

It was expected that land-clearing companies would suffer high casualty rates both from enemy action and from natural hazards. Most enemy-inflicted casualties came from mines encountered in the cut or from mortar attacks on night defensive positions. Aside from the obvious danger from falling trees, some of which ranged up to six feet in diameter, there were other natural hazards. Perhaps the most notable of these was the bee. Swarms of these insects often brought clearing activity to a standstill, and many operators had to be hospitalized, some in serious condition. Green smoke flares proved the best means for repulsing bees. No other color than green seemed effective.

On the average, a land-clearing company could be expected to clear between 150 and 200 acres of medium jungle each day. Of course, in any specific operation, production depended on many variables including terrain, weather, maintenance, and enemy action. Because of the intense command interest in land-clearing

[102]

operations, daily production reports received careful scrutiny at all echelons. Unit commanders and even the troops themselves quickly learned this fact and competition between land-clearing companies became intense. The most forthright production report ever received was submitted by a company commander whose Rome Plows had all become hopelessly mired in the monsoon mud before reaching the cut area. His report for the day in the line reserved for "acres cleared" was the most famous one-liner in land-clearing history. It said, "one tree." Needless to say, this report created great concern as it filtered up through channels. An investigation clearly disclosed the impossible situation of the unit; in fact, to cut down a single tree under the circumstances was a major achievement. Queried on this point, the company commander admitted that when one of his plow operators attached his winch cable to a dead tree in an attempt to extract his tractor from the mud, the tree fell over and was counted.

From a strategic standpoint, the cumulative effects of land-clearing operations in Vietnam had a decided impact as the enemy was forced increasingly to adjust to the disappearance of his operational bases or to interdiction of connecting trails. The vastly improved capability of allied forces to observe, shoot, and move throughout hundreds of thousands of acres of what was formerly "enemy country" represented dramatic progress, not only in a strict military sense but also in terms of pacification and economic development. In the wake of land-clearing operations came a distinct revitalization of the countryside as villages began to spring up in once-threatened areas, agriculture bloomed where only the impenetrable jungle had stood, and traffic appeared on hundreds of miles of roads made safer by pushing back the jungle growth that once concealed the enemy. This was accomplished at a cost, and that cost was borne primarily by the Engineer Corps soldier who served in the land-clearing units throughout Vietnam. While statistics are usually bland and often misleading, in the case of these young engineers they are extremely interesting. In most land-clearing companies, two out of three men became casualties from enemy action during a one-year tour. Those who were specifically assigned to operate Rome Plows were statistically a cinch to earn a Purple Heart. That all of them did not is attributed to the fact that some received more than one. Add to this the other physical hazards inherent in land clearing, and the occupation appears to be one to be avoided. Yet the rates at which land-clearing specialists re-enlisted or voluntarily extended their tours in Vietnam were consistently at or near the top of U.S. Army, Vietnam, statistics. Of even greater

[103]

significance is the fact that these engineer soldiers were not specially trained or screened for land-clearing assignments. In fact, many initially resisted being assigned because of what they had heard about land clearing and its hazards. Yet once assigned, almost universally these men acquitted themselves most admirably.

[104]

Go To:

Return to the Table of Contents