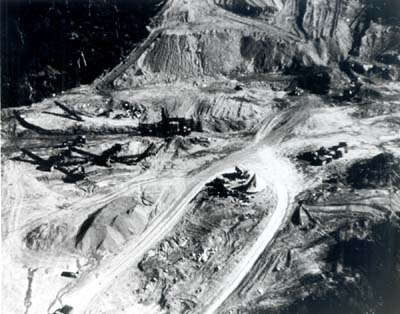

MAIN PORT FACILITIES AT CAM RANH, SEPTEMBER 1967

CHAPTER VIII

The Lines of Communication Program

In the Vietnam War, as in all wars, transportation was a big factor in military operations. The desire of the United States to improve political and economic life in South Vietnam was an added incentive to make every part of the country easily accessible to commerce and government. Strategic, tactical, and logistic mobility were essential ingredients of military success; the ability to move enough units, men, equipment, and material where they were needed and when they were needed was the index of such success. Since most existing land lines of communication in the Republic of Vietnam were either incapable of supporting American military vehicles or were subject to continuous enemy interdiction, it was necessary at first to depend heavily on water and limited air transport to provide logistic support.

The plan to move extensively by water encompassed not only the major ports of Saigon and Cam Ranh Bay and the shallow-draft ports of Qui Nhon and Da Nang, but also entailed the establishment of a series of shallow-draft ports along the coast. Through port improvement it would be possible to capitalize on Vietnam's long coastline for lateral distribution of supplies. As the larger ports developed, supplies could be shipped by water to the smaller ports and then inland by highway or airlift either to the forward support areas being established throughout the country or directly to the combat elements.

When U.S. Army engineers landed in Vietnam in 1965, only two deep-draft ports existed in the entire country-Saigon and Cam Ranh Bay. Shallow-draft port facilities existed at Nha Trang and Qui Nhon, and there were several beaches along the coast over which cargo could be transported from ships lying offshore. Although the Army lacked ships to take advantage of the shallow ports, this lack was offset to some degree by unloading cargo across the beaches. The two deep-draft ports with their severely limited berthing facilities were totally inadequate for handling the volume

[105]

of American materials being shipped to Vietnam during the troop buildup.

The 497th Engineer Company (Port Construction), the Army's only such company in 1965, estimated the requirements and made plans for both long-range and short-range port facilities throughout South Vietnam, except in I Corps, which received its support from the Navy. Over-all plans called for making Saigon and Cam Ranh Bay into major logistical bases, and Qui Nhon, Nha Trang, Phan Rang, and Vung Tau into minor support bases. As the ports were developed a variety of attendant projects were undertaken in addition to the basic pier construction. Barge off-loading facilities, airfields, ramps for landing craft, and logistical storage facilities were incorporated in the plan.

The greatest single aid in the rapid development of port sites in Vietnam was the DeLong pier. Essentially one version of this pier consists of a 90x300-foot barge supported by eighteen tubular steel caissons 6 feet in diameter and 50 feet long. These caissons are placed in, collars attached to the piers and are pressed into the harbor bottom by pneumatic jacks that are a part of the collar apparatus. Therefore the pier is further jacked up on its caisson legs to the desired elevation above the water surface.

Each DeLong pier provided berthing for at least two ships simultaneously, and use of these finger or T-shaped piers made possible the rapid development of deep-draft ports at Qui Nhon and Vung Tau and expansion at Cam Ranh Bay. The first DeLong pier assembled in South Vietnam was at Cam Ranh Bay. Its installation required the efforts of sixteen men for forty-five days; a timber pile pier of comparable dimensions would have required at least six months' work by a platoon of forty men with special equipment. DeLong piers were emplaced as quickly as they became available.

A wide spectrum of engineer activity accompanied the development of port facilities at Cam Ranh Bay. An 800-foot rock causeway and 80-foot bridge span previously discussed were constructed to provide access to the first DeLong pier, a large cargo-handling area was prepared, and a roadnet capable of supporting the inland shipment of cargo was build. The first tactical airfield with a runway of expedient surfacing to support jet fighter aircraft was constructed, and along with it a 400-foot timber jetty to assist in pumping fuel from the piers to the air base.

Eventually Cam Ranh Bay was served by four DeLong piers as well as facilities for offloading shallow-draft vessels. In addition to being the largest logistical storage area in the republic, Cam Ranh Bay became one of the largest and most effective ports in Southeast Asia.

[106]

MAIN PORT FACILITIES AT CAM RANH, SEPTEMBER 1967

Farther up the coast, elements of the 497th Engineer Company and the 937th Engineer Group were occupied with increasing the capacity of the port at Qui Nhon. Since is was a shallow-draft port, ramps for landing craft were needed, but there was no suitable land available for them. As a first step, therefore, a new jetty was extended from the shore at Qui Nhon with approximately 45,000 cubic yards of fill to create a usable area 620x360 feet. This extension provided excellent landing facilities for the shallow-draft landing craft and more than doubled the storage area of the port. When Qui Nhon was upgraded in February 1966 from a support area to a logistical base, storage capacity was expanded even more. In addition, deep-draft berths were provided through the installation of DeLong piers and permanent LST ramps.

Port facilities in Saigon were quickly swamped by the heavy volume of war materials that poured in during the buildup. Numerous improvements were made along the original pier lines and approaches. To relieve the congestion on the Saigon docks and in the city itself, the Engineer Section of US Army, Vietnam, planned a completely new port on the Saigon River upstream from the city. Designed and constructed primarily by civilian architects and contractors and christened Newport, it became a US Army port and

[107]

EXPANDED PORT AT QUI NHON, SUMMER 1967. Island is man-made.

assumed responsibility for handling the greatest proportion of the war-related shipping into the Saigon area. Engineer troops of US Army, Vietnam, contributed to construction by performing a number of minor tasks. When the port was nearly completed, engineer port construction specialists installed chain link fencing completely around the pier face from deck to river bottom to protect it against underwater swimmers and explosives, and mounted floodlights under the pier deck to improve night surveillance.

Air terminals were built in each major port complex and many of the minor ports. The lack of airfields throughout the nation created a demand for a large amount of engineer construction during the latter half of 1966. General Westmoreland early in the buildup expressed his desire that every point in South Vietnam be within twenty-five kilometers of an airfield. Such a strategy required not only the building of new airfields in what was often inhospitable terrain but also the reconstruction of old ones. Many of the existing airstrips had been built by the French and were paved with little more than a surface treatment from one-half to one inch thick-hardly adequate for American C-123's and C130's. Forward airstrips were often the only means of resupply for

[108]

NEWPORT, THE ARMY ADDITION TO THE PORT OF SAIGON

large-scale combat operations. Contractors were used to develop major permanent airfields for jets in the more secure areas while troops constructed forward strips at an astonishing rate to support combat operations and to permit forward supply. Army logistics and engineering were adapting to the airmobile concept.

The Army had been training airborne engineer units since the inception of airborne combat units, but it was not until the beginning of counterinsurgency operations in Vietnam that the airmobile concept of engineer operations came into its own. The term "airborne" was normally applied to units or operations involving parachute delivery of assault troops and subsequent delivery by large Air Force cargo planes to supporting airfields. "Airmobile" on the other hand was applied to units and operations using helicopters either independently or in conjunction with Air Force cargo planes. Throughout US operations in South Vietnam scores of Special Forces camps and remote fire support bases required engineer support for building gun pads, airstrips, and defensive positions. The inaccessibility of many of these installations to surface transport and the likelihood that the enemy was near made airmobility a necessity.

Because of the nature of their mission, airmobile engineers had to be capable of segmenting their equipment for air transport by the giant Sky Cranes or Chinooks. The limited capacity of tactical

[109]

ARTILLERY FIRE SUPPORT BASE known as Landing Zone Uplift under construction

by 35th Engineer Battalion.

support air transports made it necessary for airmobile engineer units to have specially designed miniaturized equipment. Such units had small 3/4-ton dump trucks instead of the standard 5-ton; D5 and D2 dozers instead of the larger, heavier D7; and their scrapers were designed to be split into sections for air transport. With their unique equipment and capabilities, the airmobile engineers could function wherever their assistance was required, often in areas cut off from the outside world except for radio communications and resupply helicopters. The airmobility of US Army engineer units contributed greatly to their "go anywhere, do anything" reputation.

In II Corps the airmobile 8th Engineer Battalion spent the early months of 1966 mastering the problems inherent in the rapid construction of forward airfields. Within a six-month period the battalion constructed nine airfields capable of handling cargo aircraft ranging from the smaller C-123's and CV-2's to the larger and

[110]

heavier C-130 transports. Over a two-year period from mid-1965 to mid-1967, US Army engineer units installed or rehabilitated more than eighty airfields.

The construction of an airfield at An Khe, built initially with an expedient surfacing by the 8th Engineer Battalion for its parent unit, the 1st Cavalry Division (Airmobile), was a testimony to the proficiency developed by Army engineer units in tactical airfield construction. Working seven days a week and nearly twelve hours a day, the engineers of the 8th Battalion combined speed and technical expertise to meet imposed completion dates. Even at that rapid pace, maintenance and repairs on construction equipment were not neglected; spaced during the twelve-hour day were three forty-minute maintenance periods. This valuable time committed to maintenance increased the useful life of the machines and decidedly lowered deadline rates, factors particularly important in view of the lighter construction equipment available to the airmobile battalion.

The construction of the runway at An Khe required extensive earthmoving and the development of special techniques to control

[111]

erosion. After the runway surface was graded, it was compacted and sealed by a rubber-tired roller. The hard-packed surface that resulted could withstand heavy tropical rainfall with little or no erosion. The final phase of construction involved the application of the newly developed T17 membrane, a tough rubberized fabric, to the surfaces of the runway, taxiways, and parking area. Emplacement time for the membrane averaged half an hour for each hundred feet. While a force of about a hundred men installed the membrane, others dug anchor ditches to hold the edges in place. As a final touch, a skid-proofing compound was applied to the surface of the membrane.

Other divisional battalions as well as many of the nondivisional battalions soon adapted the experience of the 8th Engineer Battalion to their own operations with notable success, even though they lacked some of the flexibility afforded by the light, sectionalized equipment peculiar to the airmobile units. As early as the late months of 1965, the Army Engineer sought more airmobile engineer equipment. Requests for an airmobile light equipment company from the United States were consistently refused because of the need for strategic reserves at home. Thereafter requests were repeatedly entered for shipment of individual items of airmobile engineer equipment. However, the continuing expansion of usable road networks reduced the urgency for wide distribution of that equipment throughout engineer units. By mid-1967 a number of light dozer tractors had been received and allocated by US Army, Vietnam, to selected engineer units. Later, provision was made for stockage of limited amounts of specialized equipment within Army depots. These engineer items could then be issued under control of the Army Engineer.

The T17 membrane proved highly successful as an expedient airfield surfacing material. It was easily and quickly installed and provided a durable, waterproof, dustproof surface. When placed on a well-compacted, crowned subgrade, properly joined and anchored and afforded adequate shoulder drainage, it was one of the most effective new materials for fast airfield construction to come out of the war in Vietnam. For sustained heavy use by cargo planes, the T17 membrane required replacement by the more sturdy steel or aluminum matting and ultimately by concrete. These replacement tasks were normal functions of support engineers.

Forward airfield construction in South Vietnam was a science in itself. The finished product was crude when compared with more permanent airfields, but in Vietnam, where the success of a combat operation often depended on the quick construction of one forward airstrip, speed and basic utility were far more important than a

[112]

INSTALLING T17 MEMBRANE AT BAO LOC

sophisticated product. Through their proficiency in operations such as the construction of the An Khe airfield, the US Army engineers made a significant contribution to the success of the combined arms team.

The customary tactical or logistical support airfield in South Vietnam called for a 3,500-foot-long surfaced runway, 60 feet wide, with a surfaced parking area for three C-130 aircraft. There were technical limitations on slopes, grades, and approach clearings, and a drainage plan had to be developed and incorporated during, if not before, construction. Air Force representatives certified the technical adequacy of runways and hardstands (parking areas) before the C-123 and C-130 aircraft were allowed to operate on the field. Protective earthen mounds six to ten feet high, called berms, were necessary for both ammunition and fuel storage to restrict and control potential damage from enemy attack. In World War II and the Korean War the standard expedient surfacing had been pierced steel plank. The residual Army stocks of this material were in South Vietnam even before the troop buildup and were widely used for surfacing in truck parks and elsewhere. The large holes in the expanded metal added to mud problems in South Vietnam and the engineers greeted with relief the arrival of solid steel plank, designated M8A1. Another metal surface consisted of interlocking rectangular panels of aluminum-two flat sheets bonded to internal

[113]

Construction Data on An Khe Airfield

|

Equipment |

No. of Items |

Equip. Hours |

Man-Hours |

|---|---|---|---|

|

Total |

3,811 |

24,858 |

|

|

Tractor |

3 |

747 |

21,628 (Construction of airfield facilities) |

|

Tractor |

4 |

545 |

|

|

Grader |

4 |

981 |

3,230 (installation of T17 membrane) |

|

Loader, 2 1/2-cubicyard |

1 |

231 |

|

|

Tractor,dozer, small |

2 |

359 |

|

|

Roller,pneumatic |

2 |

244 |

|

|

Truck, dump |

6 |

731 |

structural dividers. This material, purchased by the Air Force, was acceptable for fighter planes and was used on the 10,000-foot runways at Cam Ranh and Phan Rang. Later it was also used on selected Army airfields, for example An Khe and Cu Chi. Still another surface, the square MX19 aluminum panel with a honeycomb interior, arrived in South Vietnam in 1966 and proved preferable for heavily used forward airfields.

One great trouble the engineers had with all prefabricated metal surfacing in South Vietnam was that they could not seal water out of the joints between panels. The volume and frequency of rainfall contributed to recurrent failure of sections of trafficked runways, thus burdening engineer units with extraordinary maintenance and replacement tasks. Many attempts were made to overcome the airfield maintenance problem, which grew with each additional field that was built. Engineers tried laying the T17 membrane below the metal or on top, and introduced asphalt products, but they found all their attempts less than satisfactory. Since each takeoff and landing produced powerful thrusts against the surface, some means of anchoring was necessary to prevent "creep" of a runway, and yet any adequate anchorage provided surface water with a simple access to the runway subgrade. Upon the urging of engineers, the matting designers have since developed rubber inserts that fit into the panel edges of the MX19 matting to produce an effective seal against water seepage. All the required runways had been built, however, before the improvement could be adopted. The maintenance and replacement problem remained. It

[114]

is to be hoped that in future operations fewer men will be needed to deal with the problem of water on airfields.

Helicopters brought with them a new set of problems for engineer soldiers. The sandy or dusty soil which was commonplace throughout most of Vietnam during the dry season was a serious consideration in heliport construction. During takeoffs and landings the downblast of air from the main rotor blades of the helicopters pushed thick swirling clouds of dust into the air, causing damage to engines and rotor blades as well as restricting pilot visibility. Without adequate dust control, the damage done by dust to turbine blades could be just as effective as combat action in reducing the number of aircraft available.

Aluminum or steel planking was an effective means of dust control but it proved to be economically unfeasible for use on hastily constructed tactical facilities built solely for helicopters. Diesel fuel, distributed from spraying systems mounted on trucks or trailers, was used extensively to keep down dust for short periods of time. The 45th Engineer Group (Construction), commanded by Lieutenant Colonel George M. Bush, made an important contribution toward dust control with the development of a new style of heliport called the minipad. The important innovation in this new design was the use of peneprime, a dust palliative material with an asphalt base. When an area had been selected as a helipad site, it was leveled, graded and compacted, then sprayed with peneprime. The asphaltic substance when sprayed onto sand bound small particles together, making the surface dust-free. Peneprime required little time to set, and the construction of a minipad could be begun immediately after its application to the surface.

At Tuy Hoa Company B of the 39th Engineer Battalion used this new method to reduce sharply a severe dust problem which had greatly limited aviation support available to combat operations in the area. The entire project consisted of sixty-four minipads and two refueling pads and was completed in just six days.

Development of the land lines of communication appeared to lag far behind the improvements in air and water lines because it was a much larger problem. Movement by highway increased throughout 1966 and continued to increase at an accelerated rate thereafter. By mid-1966 General Westmoreland had let it be known that in his estimation US commanders were too timid about making use of the roadways and relied too heavily on limited helicopter resources as a means of transportation.

[115]

As early as April 1966 the Army Engineer had recommended to Lieutenant General Jean E. Engler, deputy commanding general of USARV, the construction of an entirely new road connecting Long Binh with Cu Chi, the base camp of the 25th Infantry Division. The proposed two-lane paved highway would require the building of a large bridge near Phu Cuong but could be completed by November. When the commander of II Field Force, Lieutenant General Jonathan O. Seaman, was briefed on the proposal, he was loath to commit tactical troops to a campaign intended to improve security for the engineer road and bridge builders. However, after his views were presented at US Army, Vietnam, headquarters, General Engler approved the highway and detailed planning began.

Until June 1966 the Vietnamese Bureau of Public Works and the South Vietnamese Army engineers had done very little work on roads and bridges. US Army engineers, while concentrating on base development and vertical (above ground level) construction to house and supply the growing number of allied forces, had already tackled the problem of road improvements, primarily in connection with tactical support operations and with their own needs for surface movement around the country. After General Westmoreland's reference to commanders who were too timid to use existing road systems, US engineer group commanders were directed to provide support for the road and bridge building operations of the South Vietnamese and to issue appropriate materials to them on condition that bridges and roads be built to US specifications. Characterized by insufficient subgrade and poor drainage, existing roadways were in serious disrepair and required continuous maintenance. By adhering to US Specifications, the South Vietnamese developed the ability to build roads that could sustain the volume of heavy traffic generated by the war.

After numerous and extensive planning conferences, Headquarters, US Military Assistance Command, Vietnam, issued directives outlining the construction program for the land lines of communication for engineer troops. South Vietnamese Army engineers, as stipulated in a directive, continued to be responsible for road and bridge construction in the more pacified areas. Those roads used primarily by allied forces for tactical or logistical operations were the primary responsibility of American engineer troops. The priorities for construction, maintenance, and upgrading of roads and bridges were to be determined by the various corps commanders, subject to authorization from the Office of the Directorate of Construction.

The lines of communication program in Vietnam was one of the largest single engineer projects ever undertaken by the United States

[116]

UNIMPROVED STRETCH OF HIGHWAY 1 NEAR CAM RANH

military in a foreign country. When completed, this massive construction project Would tie together the major population centers of the country with 4,106 kilometers (3,038 miles) of modern high-speed highways.

While the formal road construction program was not fully defined until 1968, a considerable amount had been accomplished before that time. The 35th Group had begun paving operations at Cam Ranh and had proceeded with National Route 1 both north and south, using standards set by US Army, Vietnam. It had established by early summer of 1967 a factory for fabricating reinforced concrete 20-foot spans to use in place of culverts on the highway. The 159th Group was paving Route 15 and had built a causeway across a water gap near Vung Tau. A significant start had been made by the 45th Group on paving Route 19 between Qui Nhon and Pleiku. Tactical priorities had precluded an all-out effort by engineer troops on a national road construction project until the military situation demanded less combat support. By 1968 base development had reached a stage Where engineer manpower and equipment could be gradually shifted to the lines of communication program. In the spring of 1970 more than 11,000 men of the 26,000 in the US Army Engineer Command, Vietnam, were engaged in some aspect of the highway construction program.

[117]

The repair and improvement of secondary roads was initially the responsibility of Vietnamese engineer units. From time to time as early as 1966, US Army engineers had worked on small stretches of secondary roads where immediate gains could be made in promoting commerce, travel, and communication. In late 1969 the secondary road network received more formal attention. Concerted effort was devoted to establishing priorities with the result that by mid-1970 some 75 percent of the scheduled repair and upgrading had been accomplished. The impact on certain localities was more noticeable than that on the country as a whole; with the opening of each new road from a small community there was a dramatic revival of local commerce.

The wide variations in terrain and climate in Vietnam posed many unusual problems for the engineers and called for new methods of highway construction.

At times mud and a critical shortage of rock threatened to impede seriously any construction of roads capable of supporting heavy traffic in the Mekong Delta region. To cope with these natural obstacles a process known as clay-lime stabilization was de-

[118]

veloped. In this process clay was scraped out of the rice paddies to form a roadbed several feet above the water level. A predetermined amount of lime was spread over the surface of the clay with large scrapers, then mixed into the clay with a rotary tiller or disc harrow. Finally, the mixture was mechanically compacted and allowed to cure. The process was repeated with several eight-inch layers of subbase after which an eight-inch layer of crushed rock was added on top. The surface was then ready to be paved with a double course of asphaltic concrete.

The reaction of the lime and clay was basic to the process. The lime caused the clay to coagulate into particles the size of grains of sand. These larger particles then adhered to one another, forming a considerably more stable base than clay alone. The lime-clay stabilization process had been used successfully in airfield construction in parts of South Vietnam, and its use in road construction was an example of applying lessons learned to good advantage. Nearly all of the fifty-nine kilometers of Route 4 in the IV Corps area were constructed by using this method.

A process similar to clay-lime stabilization was used on portions of Route 13 in III Corps. In this case the natural soil was a silty sand to which Portland cement was added instead of lime to build a conventional soil-cement subgrade that was topped with a single layer of asphaltic concrete. Wherever problems arose in the lines of communication program, engineers repeatedly applied their pro-

[119]

PERMANENT BRIDGE ON HIGHWAY 19 BETWEEN QUI NHON AND AN KHE replaces tactical

one-lane Bailey bridge.

fessional knowledge in devising solutions occasionally as unusual as the problems themselves.

The restoration and construction of bridges was an essential part of lines of communication development. To link all the stretches of paved highway, construction plans called for building approximately 250 new bridges. Totaling 11,300 meters, these new bridges, in addition to older but still serviceable spans, would give the republic a network of uninterrupted highways stretching from the Mekong Delta to the demilitarized zone and from the seacoast to the western borders.

The bridges were the most vulnerable links of the highway system, and engineer commanders were deeply concerned for their security. Under cover of darkness, a few determined Viet Cong could sneak to a newly built bridge and with a well-placed satchel charge of explosives destroy the result of months of engineer work.

[120]

Various methods were devised to provide adequate bridge security beyond the scope of ordinary patrolling.

Since darkness was the enemy's greatest ally, the engineers endeavored to turn night into day. Bridge lighting systems were designed as part of the construction and gradually advanced in efficiency to the point that soldiers patrolling the bridges and surrounding areas at night had fair warning of suspicious floating objects and enemy soldiers.

Other methods were developed to frustrate enemy demolition teams. Antiswimmer devices, mine booms, and several types of bridge and pier protective systems were used to enhance security. One common antiswimmer device consisted of concertina wire suspended from floating buoys and secured on the river bottom. Tidal fluctuation, prevalent in most of Vietnam's waterways, caused the concertina to shift and agitate unpredictably, discouraging swimmers from trying to pass through it. Mine booms were employed to arrest or detonate mines intended to float with the current into the pilings of the bridge. Such booms were constructed of heavy timber attached to steel cables and extended across the river a short distance from the bridge. Several feet of chain link fence was usually hung from the timbers to catch slightly submerged mines.

Two distinct pier protection systems were used in Vietnam. The first type that was tried was referred to as a chain link fence standoff, and consisted of steel beams driven into the river's bed with fencing and concertina hung from the beams. This system is still used in waters reaching depths of forty feet or more. Variable tides and currents tended to dislodge and bend the beams, however, and in a waterway with a rocky, muddy bottom it was difficult to achieve equal penetration of the beams.

A low-cost, highly flexible flotation system known as a floating catwalk was designed to function in regions with extreme tidal variations. Using as buoyants either styrofoam or floating steel balls called ping pong balls, the system could be prefabricated easily and then floated to the bridge site for installation. Once emplaced and capped with wide wooden platforms, it was connected with chain link fence and the interior was filled with concertina wire. This floating catwalk provided an advantageous observation post for guards, who could walk completely around the bridge pilings at water level.

Although the efforts of many agencies went into the lines of communication program, the construction directorate of the Military Assistance Command maintained over-all supervision and co-

[121]

BRIDGE PROTECTED WITH CAGES AGAINST SABOTAGE on Highway 1 near Bong Son.

ordination of the program between the various US agencies, the Army of the Republic of Vietnam, and allied forces in Vietnam.

One purpose of the highway program was to facilitate the movement of military supplies and increase the flexibility of tactical maneuver. In previous wars when adequate roads were lacking temporary military roads were constructed solely to meet military needs. In Vietnam, however, the nature of the war and the tactics employed were very different from those of previous American conflicts. The desire of the United States to improve the economic and social conditions of the people as well as to improve the military situation fostered the development of dependable roads of good quality.

Even more important was the contribution the program made to the pacification effort. By making travel easier and safer, communication between the villages and the cities-socially, economically, and politically-was increased. New and better roads enabled the farmer to transport his products farther and faster. Goods from cities could reach more rural markets and thereby contribute to

[122]

GRAVEL PIT AND QUARRY

NEAR AN KHE

raising the standard of living in these areas. Engineer bridge builders were gratified to witness the surge of civilian traffic across their roads and bridges.

On 1 February 1970 the goal for the paved highway portion of the road program was set at 4,106 kilometers. As of that date, 40 percent of the proposed roadways had already been completed. The US Army engineer troops along with South Vietnamese engineers and engineers of other allied forces in Vietnam were responsible for two-thirds of that construction. Nevertheless, these figures do not present the whole picture of the road construction program carried out by the US Army engineers. A great portion of the effort involved in the finished product was expended months and years ahead of the actual construction. Before any permanent highway systems could be constructed, suitable natural resources such as rock and sand had to be found. Much effort in the highway program was consumed by the widening and reconstruction of the foundation of existing roads in preparation for paving.

Development of Vietnam Resources

When US Army engineers first arrived in Vietnam in 1965,

[123]

there were only a few rock quarries, developed by the French, in operation. Rock was a scarce and critical resource in South Vietnam where much of the terrain was sandy and marshy. Since construction of base camps and tactical roads was dependent upon adequate supplies of rock for foundations, a great deal of emphasis was placed upon the development of rock quarries and crusher sites.

By mid-1970 there were eighteen US Army rock-crushing operations throughout Vietnam. During 1969 US Army statistics show that more than 70,000 tons of rock were used by Army engineers every week, a rate that more than doubled in 1970. Most of this rock was used in landfill, base course construction, and asphalt production in support of the lines of communication program.

To build roads in the Mekong Delta region, where simply finding dry ground could sometimes be a problem and where accessible rock deposits were virtually nonexistent, it was necessary to transport large quantities of rock into the area. A program for this purpose was developed in early 1967 and by 1968 was keeping more than 150,000 tons of rock per month moving by barge to offloading sites throughout the delta from quarries at Vung Tau, Thu Duc, Nui Sam, and Nui Sap.

Asphalt plants for the preparation of hot surfacing material were usually built beside the quarries. Of the eleven asphalt plants that were scattered throughout Vietnam in 1970, all but two operated in conjunction with quarries. The other two plants were located at sites near paving operations; rock was trucked to the plants from quarries and stockpiled to be used as needed.

A major innovation in the lines of communication program was the introduction of specialized road building equipment into US Army engineer units to supplement the units' own organic equipment. In December 1968 a special purchase of equipment was undertaken with Military Construction, Army, funds. The 669 items of equipment purchased supplemented every phase of road construction. Among the most important items were eight 250-tonper-hour rock crushers and 226 12-cubic-yard dump trucks. The crushers played a vital part in the production of large quantities of rock. The trucks in most cases were simply added to the great number of standard 5-ton Army dump trucks which had been hard pressed to meet hauling needs. Quarry operations were also supplemented with tracked pneumatic drills, 6,000-cubic-foot-per-minute air compressors, ground-level rock feeders, and six-cubic-yard scoop loaders. Other road construction items included several types of

[124]

compaction equipment, soil stabilization plants, asphalt distributors, and pavers. Special purpose items such as the heavy-duty D9 bulldozers, excavators, backhoes, and water distributors rounded out the equipment needs.

Lines of Communication Maintenance

The enemy persistently tried to interdict principal lines of communication in order to impede reinforcements moving to units under attack, prevent resupply of ammunition and other supplies, and minimize the use of US and Free World forces mobile resources. Bridges and culverts were blown; roadblocks of various descriptions were thrown up; and mines, both pressure and command-detonated, were used extensively by the enemy in attempts to disrupt the use of main traffic arteries.

The Army engineers needed all their Yankee ingenuity and resourcefulness to repair continuous damage to roads, remove roadblocks, and clear away mines.

The engineer units were charged with keeping all main arteries

[125]

EQUIPMENT DAMAGED BY MINE DETONATION

open to traffic with a minimum of delay and inconvenience to the users. In many areas trucks and other organic equipment were loaded each night with laterite, crushed rock, and culvert material. At first light, reconnaissance was conducted over the roadnet in a particular area, and if any damage was detected engineer crews were immediately dispatched and repairs were promptly made.

The type of equipment available to engineer units was an essential factor in both construction and maintenance of lines of communication. As military operations continued, new and more effective equipment became available and units achieved greater capability. Engineer unit equipment eventually included armored vehicle launch bridges capable of spanning 60-foot gaps in bridges and culverts, and dry span bridges which had skeleton sections pinned together and which could be airlifted and emplaced by Chinook or Sky Crane helicopters. A 38-foot bridge could be installed in twenty minutes.

An incident on Route 4 provides an example of the expertise and proficiency gained by the engineers in lines of communication maintenance. Because Route 4 was the main supply road from the rice fields in the Mekong Delta to the markets in Saigon, its bridges were natural enemy targets. On 19 February 1968 Viet Cong forces blew a bridge over one of the tributaries of the Song Lu River near the small village of An Ngai in III Corps. The damage was dis-

[126]

covered at 0730 by a reconnaissance team from the 15th Engineer Battalion organic to the 9th Infantry Division and stationed at Dong Tam. By 0830 the team had reported the damage to the operations section at division headquarters. Headquarters then informed the II Field Force engineer section, which defined the replacement mission and sent it on to the 20th Engineer Brigade. Because of the strategic and economic importance of the bridge, its repair was classified as an immediate reaction mission. Since the bridge was within the area of responsibility of the 34th Engineer Group (Construction), that group headquarters assigned the mission to the 617th Engineer Company (Panel Bridge), the only such unit in the group.

After linking up with a prearranged security force in Dong Tam, the 617th proceeded to An Ngai. To impede repairs the Viet Cong had exploded cratering charges in the road from Dong Tam to An Ngai. The bridge convoy was preceded by fifteen dump trucks from the 15th Battalion, loaded with sand which was put down to make the road passable for the equipment of the 617th. By 1800 on 23 February a new 140-foot Bailey bridge had replaced the old destroyed span. Only 106 hours had elapsed between the time damage was reported and the time the bridge was replaced and ready for use. Such action typified the efficiency of the Army engineer organization in South Vietnam; whenever and wherever a bridge was

[127]

BAILEY BRIDGE REPLACES DESTROYED BRIDGE NEAR AN KHE

destroyed, the engineers made sure that it was repaired or replaced in the shortest possible time.

During 1968 and 1970 when large segments of the lines of communication program were completed, the nature of highway maintenance changed. Once a section of road had been paved the enemy stopped mining it, although he continued to mine the shoulders occasionally. An example of the effectiveness of pavement in reducing mining was the completion of Routes 1 and 22 from Cu Chi to Tay Ninh in the III Corps area. Before upgrading, an average of one vehicle per day was lost along this route, but once paving was completed, mine damage was almost eliminated.

One technique developed to reduce damage from the demolition of culverts consisted of welding prefabricated reinforcing steel grills over both ends of the culverts. In July 1970 the enemy attempted to cut Route 13 about thirty-five kilometers north of Lai Khe. Grills which had been previously installed kept the enemy from placing charges inside the culvert, and although both ends of the culvert were destroyed and the shoulders cratered, the pavement was undamaged. Two-way traffic continued unimpeded. Continuous heavy convoy traffic, particularly tracked vehicles,

[128]

resulted in an increasing need for maintenance of the asphalt pavements. Small patch crews were continuously used to repair potholes and prevent further pavement damage, especially during the monsoon season. In some instances an asphaltic concrete overlay of short sections was required.

[129]

Go To:

Return to the Table of Contents